Paintwork repairs in Cheltenham, Gloucestershire

VAPOUR BLASTING

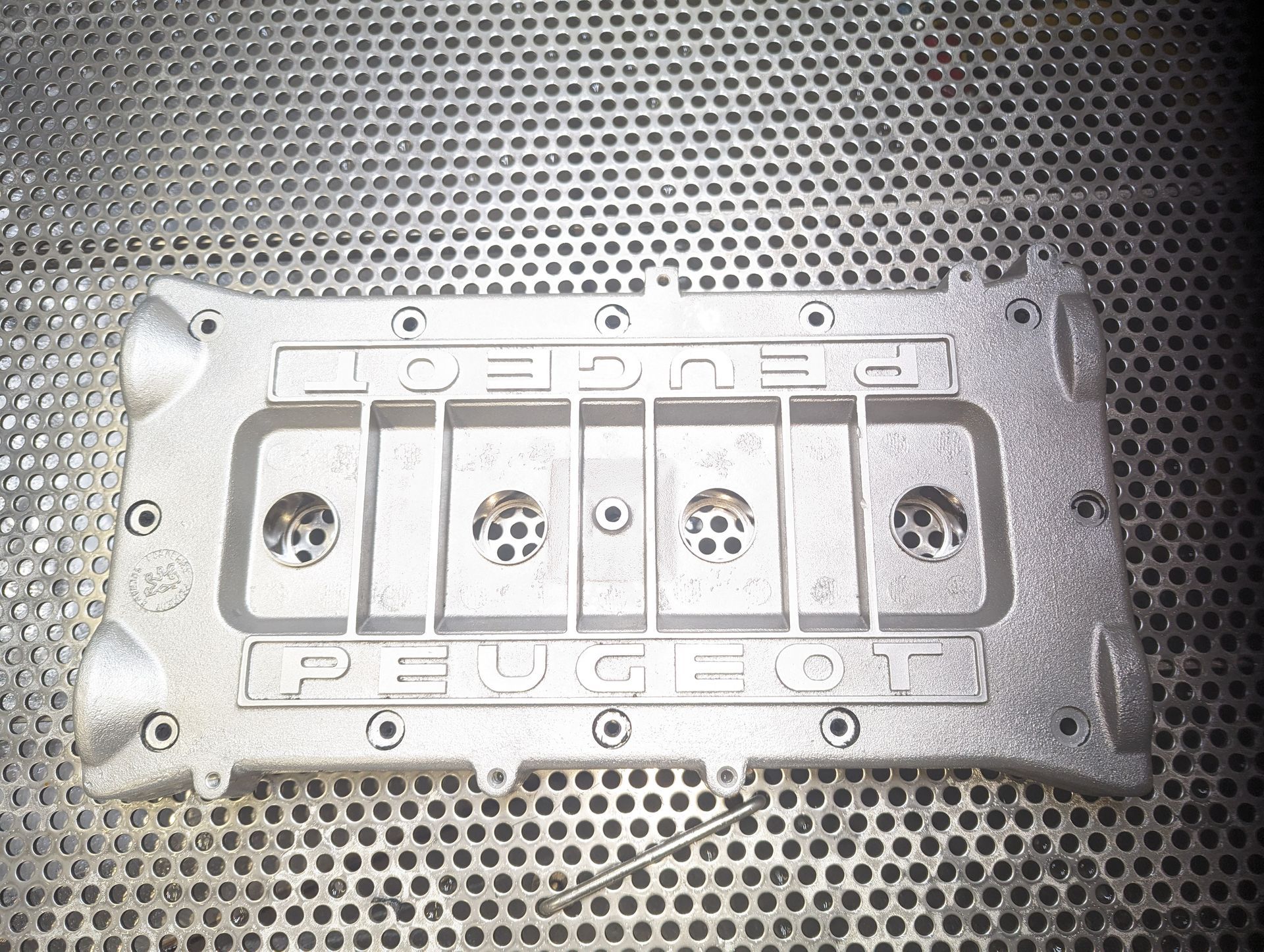

Vapour Blasting: The Ultimate Solution for Non-Ferrous Metal Restoration

At BP Motor Bodybuilders & Engineers Ltd, we utilize vapour blasting, also known as aqua blasting, as a premier method for cleaning and restoring non-ferrous metal components. This innovative process brings your parts back to their original cast satin appearance and condition, ensuring they look as good as new.

How Vapour Blasting Works:

Our vapour blasting technique combines water with non-aggressive glass beads, creating a gentle yet effective cleaning solution. This method is specifically designed to clean materials without altering the profile of the substrate. Unlike traditional dry blasting methods, vapour blasting does not etch the component; instead, it focuses on thorough cleaning.

Benefits of Vapour Blasting:

- Effective Cleaning: Removes all dirt, grit, oils, and heat staining, restoring the component to its pristine state.

- Surface Peening: The high-pressure deposition of glass particles "peens" the surface, resulting in an even, soft satin sheen that enhances the appearance of the metal.

- Non-Aggressive: The process is gentle on the material, ensuring that the integrity of the component is maintained.

If you're looking to rejuvenate your non-ferrous metal parts, our vapour blasting service is the perfect solution. Contact us today to learn more about how we can help restore your components to their original glory!

Top-quality service

VAPOUR BLASTING PRICING

We will get back to you as soon as possible

Please try again later